| TECHNICAL DATA | 120ip | 200i | 200ix | 250i | 250ix | |

|---|---|---|---|---|---|---|

| Power Supply | V~/Hz | 220-240/50 | 220-240/50 | 220-240/50 | 220-240/50 | 220-240/50 |

| Thermal Power | W | 1800 | 1800 | 1800 | 1800 | 1800 |

| Electrical Power | W | 400-700 | 400-700 | 400-700 | 400-700 | 400-700 |

| Cop En255-3/En16147 | COP* | 3.5/2.9 | 3.5/2.9 | 3.5/2.9 | 3.5/2.9 | 3.5/2.9 |

| Electrical Element | W | 1500 | 1500 | 1500 | 1500 | 1500 |

| Maximum Operating Pressure | bar | 7 | 7 | 7 | 7 | 7 |

| Sound Level @ 2m | dB | 37 | 37 | 37 | 37 | 37 |

| Refrigerant Fluid | R134a | R134a | R134a | R134a | R134a |

| DIMENSIONS | 120ip | 200i | 200ix | 250i | 250ix | |

|---|---|---|---|---|---|---|

| Dimensions Ø/H | mm | 580/1220 | 580/1667 | 580/1667 | 580/1955 | 580/1955 |

| Weight | KG | 67 | 73 | 73 | 80 | 88 |

| Air Vent Diameter | mm | 160 | 160 | 160 | 160 | 160 |

| Cold Feed & Hot Water Diameters | 1/2” | 3/4” | 3/4” | 3/4” | 3/4” |

| HOT WATER CYLINDER | 120ip | 200i | 200ix | 250i | 250ix | |

|---|---|---|---|---|---|---|

| Nominal Capacity | l | 120 | 200 | 200 | 242 | 250 |

| Material | Stainless Steel ** | |||||

| Insulation | High Density *** | |||||

| Corrosion Protection | Magnesium Anode | |||||

| Auxiliary Coil (Comp./Ø) | m/mm | – | – | 10/25 | – | 10/25 |

| Auxiliary Coil Hydraulic Connections | – | – | 1” | – | 1” |

| WORKING CONDITIONS | 120ip | 200i | 200ix | 250i | 250ix | |

|---|---|---|---|---|---|---|

| Outside Air Temperature Min/Max | ºC | -5/40 | ||||

| Maximum Water Temperature – Eco Mode | ºC | 55 | ||||

| Maximum Water Temperature – Boost Mode | ºC | 70 |

* Water temperature raised from 10ºC up to 54ºC. Air temperature 7ºC. | **High Corrosion Resistance | *** 60mm Thickness

ECO – The equipment only works as heat pump.

AUTO – The equipment works as a heat pump and with electrical elements should it be required.

BOOST – The equipment works simultaneously as a heat pump with the electrical element.

VACATIONS – Allows the user to setup a certain number of days on which the system will be off. On the last days the system will perform a anti-legionella cycle.

DISINFECT – Heating cycling at a higher temperature in order to disinfect the water (legionella) May be programed automatically or manual.

PV FUNCTION –Increases the water temperature set point when PV in producing electricity heating water for free.

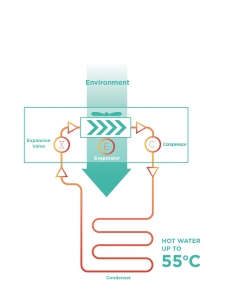

Working Principle

Working Principle

There is a cooling liquid that is pumped to an outdoor heat exchanger (evaporator).

Here the liquid, with the help of a fan, absorbs the energy from the atmosphere to the temperature differential obtained outdoors. During this process, the liquid changes to a gaseous state.

The gaseous state is sucked in by the mechanical part of the system, the compressor. Here it is compressed, the pressure goes up and consequently the liquid temperature increases. After this, the liquid travels to a second inside heat exchanger (condenser) and transfers heat to the water in the cylinder.

The fluid goes into liquid state by cooling down. The liquid pressure is reduced due to a strangulation that happens in the expansion valve and the process starts.

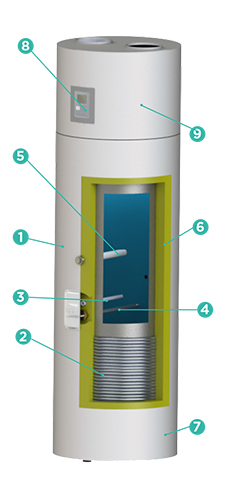

1. DHW Cylinder

2. Condenser

3. Probe Sheath

4. Electrical Element

5. Magnesium Anode

6. High Density Insulation

7. Outside Coating

8. Electronic Controller

9. Heat Pump Unit

Stainless Steel Cylinder with or without Auxiliary Coil